Silk weaving began as a thriving industry in the Spitalfield district of London in the early 1700’s when the Huguenots, (protestants), fled from Catholic France. About 50,000 of them settled in this small area of London bringing the word ‘refugee’ into the English language. They were quite prosperous people and many of them were skilled weavers. At around this time silk clothing and furnishings were much sought after, so there was great demand for the weavers’ skills. They settled into the culture with little difficulty.

The Spitalfield Act of 1774 fixed wage rates in London so several firms moved out into the Sudbury area of Suffolk. It’s a very pretty, ancient part of England which has attracted artists for centuries. Gainsborough, the portrait painter and John Constable, the landscape artist, both lived in the area which has managed to avoid the tourist invasion and remains a quiet and lovely place.

There are still two weaving establishments in Sudbury. Vanners Silk Weavers, has a pedigree which stretches back to 1730. Ironically it is the one that, because of many buy-outs and take-overs, has become totally computerized and sells to large markets all over the world.

Gainsborough Silk Co Ltd., established in 1903, produces bespoke silk furnishing fabrics in the same method and, for the most part, with the same Jacquard looms they started with. It’s customers over the years have been, Henry Ford, car manufacturer, William Morris, textile designer, royalty from around the world and museums. They are proud of their appointment to the Queen. The crest which comes with this is displayed in the very modest entrance to the building.

Appointed by the Queen

I was delighted when I was given permission to wander around and ask questions and watch amazingly skilled people work on all aspects of the weaving process. Everyone was very friendly and quite intrigued by my being in a weavers’ guild in California!

Twenty percent of the fabric is of pure silk. The rest is blended with wool, cotton or linen. The silk comes from China. There is silk filament and spun thread. They use only the filament which is reeled from silkworm cocoons and joined to produce a long flawless thread, which can be several thousand yards long. The finest thread they use is a three thread organzine which is thinner than a human hair and usually used for silk damask. I did not visit the dye house. They use a modern electronic spectrometer to mix the colors.

Winding the Bobbins |

The bobbins |

| The most experienced warper and winder, Sue Thompson, will wind 200 bobbins for a 50 metre length of fabric with a thread count of 8000. These are first placed on a creel then threaded through a wide reed. Sections from the warp are threaded through another reed about six inches wide. Each section is wound on to the drum consecutively then the drum is ready to be taken to the loom for warping. (beaming off). | |

| The new warp is tied on to the old warp with a knotting machine. It takes about four hours. They do have a couple of computer driven looms but the rest are traditional Jacquards with master weavers working quietly at their craft. They use three 1920’s Hattersley looms. It takes from four to six days to weave 50 metres of fabric. | |

green warp |

warping the loom |

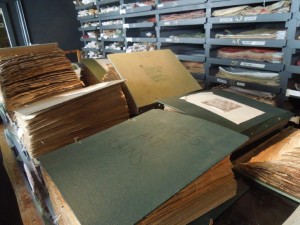

| They keep very careful and detailed records of all their products. There is an amazing room full sample books with each sample carefully documented for pattern and dyes used. I asked how they knew which book to look in and was told that sometimes they have to flip through quite a few books before they find what they are looking for. Many of the orders are repeat requests after many years. | |

Sample books |

Samples |

| This wonderful group of people has woven fabric for the queen’s carriage, for royal wedding dresses including most recently, for Cate in 2011, dress material for Michelle Obama and fabric for all manner of emirs and such like. They love their work and one woman told me she was 64 years old and had retired twice but couldn’t stand being away from there. The main aim of the company is to keep manufacturing beautiful silk fabrics in England. In this world of dizzying technology it is comforting to see these creative people produce works of art without computers. It makes me very happy to know that guilds like ours and others in many other countries are carrying on this tradition. | |

Finished materials |

Another example of their material |