Editor’s note: After graduating from California College of Arts and Crafts in 1976, Sheila developed a unique two-sided twill structure that she created using four separate warps with a single weft on a 16 harness compudobby loom. By manipulating these warps, she was able to do pictorial hangings that caught the art world’s eye and put her on the short list of up and coming textile artists.

In 2000, Sheila started exploring newer and more versatile equipment: the TC-1 and the AVL/TIS hand jacquard looms. These looms have computer interfaces to assist with patterning. The looms allow the artist a greater range in design detail because every thread can move individually. The following story starts after Sheila had become familiar with these looms and software programs and before she acquired her own jacquard loom in 2008. JF

Preparing for a museum show in 2005, I decided to weave hand jacquard tapestries as memorials to our dogs in a style reminiscent of ancient Egypt.

King Pup

Cleopetra

To my complete amazement, two weeks after I wove these Egyptian themed pieces, I received an e-mail from Peter Straus at AVL Looms in Chico, CA. The subject: “Training far afield: Hey Sheila, How would you like to go to Egypt (no kidding) to train someone on a small 336 hook jacquard? PS.

My eloquent reply was: “Huh? Look what I just wove!” I e-mailed him pictures of “King Pup” and “Queen Cleopetra”. Peter forwarded my jacquard tapestry images to Cairo and said it was my destiny to go there along with a recommendation. After several e-mail exchanges, Michael and Sevinch Deman invited me to travel to Egypt to help them with their AVL hand jacquard loom to weave prototype copies of antique jacquard ribbons.

Michael and Sevinch, a British couple living in Cairo for 14 years, own a company that employs 42 Egyptian artisans who are involved in the creation of passementerie: fancy tassels and trim for the interior design trade. They are using four passementerie looms that use a system of draw harnesses to lift various groups of warps to tie down the weft yarns as they create elaborate patterns on warps 1-4 inches wide. There are 16 pedals on the looms. The warp beams are large bobbins that are drag weighted with bricks. The artisans weave at lightning speed and use up to 16 shuttles at once!

workshop loom

yarn drying

passementerie loom innards

To keep the production going requires the rest of the workers to do supporting tasks. In various rooms they custom dye very fine rayon yarn, unskein the yarn onto spools and make the “lines” or cords that they weave with by wrapping this rayon yarn around a cotton core thread. This is done by securing a long cotton cord at one end of the long room and then securing it to a motor at the other end about 30 yards away. Next a worker takes a 1 foot long ¼ inch thick metal rod and puts 2-3 spools of rayon yarn on it. After the rayon yarn is secured to the core yarn at one end, the worker walks very slowly, hand-guiding the rayon yarn as it is pulled off the spools by the spinning core yarn. This is done with extreme accuracy! Next the weavers use these lines or cords for weft, usually using three on one bobbin. The bobbin winder is a giant bicycle wheel! More dyed fine rayon yarn is used for warp at a warp-faced sett. On some trims the weft yarn is caught around thin metal rods that come through the reed while weaving to make loops on the selvedges. After the trim is woven, other workers add the tassels, flowers, or ply the long weft loops in perfectly twisted fringe depending on the particular order. The workshop goes through 50-100 pounds of yarn a day!

various styles of tassels

In another room a worker carves the wooden forms on a lathe that are used inside some of the tassel shapes. The products are exquisite thanks to the skill of the artisans and Sevinch’s eye for gorgeous colors and designs. All the workers are men except for one woman who is allowed to work because her husband passed away. Only men do the weaving. They did let me try to weave for an inch or so on the last day!

Sheila weaving on passementerie loom

After viewing all the amazing passementerie wonders, Michael and Sevinch brought out samples of antique “tapes” or ribbons. They had e-mailed me images of these ribbons, but seeing them in person was so much better, of course! The first job was to set up the AVL hand jacquard 336 hook loom to get a high density. We were able to go from 23 epi to 138 epi using a 23 dent reed.

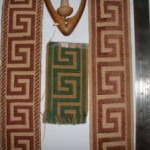

The first sample I analyzed was a classic Greek Key. I had woven a sample on a TC-1 hand jacquard loom before I went to Egypt, using various weaves – double weave, two sided twills, single warp and weft weaves so I had a small library of weaves when I arrived. Once in Cairo, I started using a one inch magnification lens to figure out the exact weave structures and added them to the weave library in the jacquard software.

Greek Key-original in center

Michael knew how to use Photoshop so, even though there is a graphic part of the ArahWeave progran used by AVL called ArahPaint, Michael preferred to use Photoshop to start and then bring it into ArahPaint. So while Michael was preparing the graphic files, I was figuring out weave structures, yarn sizes, densities and sett. Then I created a weave file by combining the image with the weaves in a giant “graph paper” that tells the loom what hooks (heddles) to lift on each pick using the loom driver software JacqPoint. With the help of two weavers, a cotton warp was put on the loom and we wove the first sample! We all were happy to see ribbon coming off the loom. After weaving it with a single shuttle we then tried the Greek Key with a double weave just to get an idea of a reversible ribbon. On this warp we also tried a few more designs of graphic images from a Dover Book of patterns.

Celtic Motif-original on top

Next we started on a beautiful ribbon made with gold thread. It has a combination of a Celtic motif with a stylized flower. We used a lurex yarn to get the gold effect and wound the next warp with black and grey rayon at 92epi. These weaves required some double weave areas, some single weave areas in twills and plain weaves, some weft floats. It appeared that in the original, one of the warps was on a second beam to allow greater take-up but we couldn’t do that. A second beam could be added in the future but, for now, I created weaves that would not make one third of the threads get tighter and tighter as we wove. When this one came off the loom Sevinch said “It’s the most beautiful tape in the world!” She was thrilled that the loom was being used. I was very relieved. It was like magic seeing the designs come out on loom.

Diamond pattern-original on top

We proceeded to a diamond pattern with some colors in it. I redesigned the back so that there were no floats so it would be more practical. Again when this one came off the loom Sevinch said “This is the most beautiful tape in the world!” This was going to be hard to keep up!

The next batch of ribbons were sett at 138 epi with a very fine rayon yarn. The idea was to do a fine detailed image in two colors. With the warp sett so closely it was hard to get many picks in.

These designs ended up coming out elongated but could be modified. This sett almost looked too commercial. We had also woven a sample with Michael and Sevinch’s names on it for the idea of custom ribbons along with several other designs – too many to include them all in this article!

original oriental motif

oriental motif prototype

The last design had an oriental theme. This one was similar in weave to the other black and gold pieces and fun to do. If the warp color sequence on the loom was off by one thread from the weave file it would throw the weaving off by placing the grey and black threads in the wrong place! Again Sevinch and Michael were very pleased. We had covered a lot of ground!

My twelve days in Egypt had passed by quickly and I was sorry to leave. The weavers had gotten used to me coming and going every day. We had developed a bit of a rapport with the help of Mona, the translator. On the last day, the workers made me the tassel with the colors of Egypt as a small gift. I was touched. I had given them reproductions of some of my tapestries. Even though I worked 6 days a week 9:00am to 7:30, I loved it. It was quite a challenge but very rewarding. I hope that they will eventually be able to add a line of handwoven jacquard tapes to their line of fine products.

At the end of the twelve days in the workshop, Bill and I were able to travel south up the Nile to see the temples of Luxor and Karnak. The architecture is unbelievable! One day we spent going to see the Valley of the Kings and Hatsheput’s temple. Words can’t describe the wonder and awe we experienced when descending into tombs still colorful after 4,000 years! I feel very fortunate that my weaving skills took us on a great adventure. Hmmmm…what shall I weave next?

This article was originally written for the Jacquard Study group of the Complex Weavers.

The next article is about Inkle weaving